Swagelok Essentials

Tour this section to see designs, ways to customize and more.

Essential Training in Fluid System Fundamentals

Swagelok® essentials training courses provide critical skills for developing, building, and maintaining dependable fluid systems. Taught by Swagelok-certified trainers at locations and times convenient to you, these courses provide the foundational knowledge and techniques needed to build and operate high-performing fluid systems.

| Topic | Date | Location / Time | Registration Deadline |

| Alloys/Corrosion/ Material Selection |

December 6, 2021 | Virtual: 10:00 am–12:00 pm (EST) |

December 5, 2021 |

| NACE | December 7, 2021 | Virtual: 10:00 am–12:00 pm (EST) |

December 5, 2021 |

| Hydrogen | December 8, 2021 | Virtual: 10:00 am–12:00 pm (EST) |

December 5, 2021 |

| Elastomer Seals | December 9, 2021 | Virtual: 10:00 am–12:00 pm (EST) |

December 5, 2021 |

| Additive Manufacturing | December 10, 2021 | Virtual: 10:00 am–12:00 pm (EST) |

December 5, 2021 |

About The Course

Topics

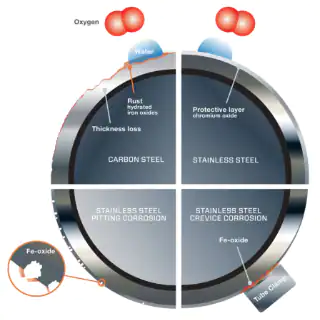

- The principles of materials science, corrosion, and other factors affecting material properties

- Different types of corrosion and how specific alloys resist corrosion

- How to select optimal materials of construction for demanding applications based on pressure and temperature ratings, corrosive threats, and compliance

- How to select proper components to address sour gas corrosion and NACE standards

- Critical concepts covering the nature and behavior of materials, including an atom-level view of metals, as well as the microstructural characteristics and mechanical properties of materials

Target Audience

- Engineers, managers, supervisors, buyers or purchasing agents, technical associates, and anyone involved in the material selection process

- Newer team members seeking basic training or experienced professionals who want a refresher

Course Length

Available virtually as a full-day course or in two-hour sessions spread across multiple days. Attendees can also choose to attend two-hour sessions on an à la carte basis to learn about specific topics of interest, such as alloys/corrosion/material selection, NACE, working with hydrogen, elastomer seals, and additive manufacturing.

Your Instructor

Dr. Gerhard Schiroky, Principal Scientist

Gerhard joined Swagelok in 2000 and has been helping customers find solutions to meet their materials requirements ever since. Gerhard has an in-depth knowledge of materials-related industry standards and standard specifications, and he has authored a variety of technical publications on topics such as 316L stainless steel corrosion, the effects of alloy composition, fluid dynamics, and materials science. He routinely provides customers with a better understanding of the NACE MR0175/ISO 15156 international standard for the selection of materials for sour gas applications, and he has developed roadmaps for improved and new alloys from which future fluid system components have been constructed. Gerhard received his doctorate in materials science and engineering from the University of Utah and he has been named on over 20 patents.

Dr. Robert Bianco, Senior Materials Scientist

Bob joined Swagelok in 2017 as a materials expert and technical lead for Swagelok’s additive manufacturing program. Having worked for nearly 30 years in applied R&D organizations, Bob helps customers develop materials for unique applications and protect materials from degradation in their environments. Prior to joining Swagelok, Bob helped develop protective coatings for the prevention of oxidation and material systems for advanced energy conservation applications. He also taught courses on materials science, additive manufacturing, high-temperature oxidation prevention, and stainless steels. Bob received his doctorate in metallurgical engineering from The Ohio State University and he has authored or coauthored 12 patents, more than 50 technical articles, and two book chapters on novel materials or coatings compositions and related performance test results.

How to Register

Register for one of the scheduled programs listed below, or email analyticaltraining@swagelok.com to request private, on-site training. Your local authorized Swagelok sales and service center will follow up with full details.

Explore Training Resources

Why Materials Science Training Matters to Oil and Gas Instrumentation Engineers

Fluid system training is critical in oil and gas applications around the world. Learn more about how technical trainings can make a difference for your facility.

Selecting Materials for Corrosion Resistance

An offshore platform can have nearly 50,000 feet of tubing, more than 20,000 fluid system components, no fewer than 10,000 fittings, and as many as 8,000 mechanical connections. No wonder choosing corrosion-resistant material isn’t easy. Learn how to make choices right for your application.

Enhance Safety and Save with Optimized Materials

Discover how offshore platform owners can optimize their material selection for tube and tube fittings to control costs and enhance safety in a variety of applications.

Four Answers on Material Selection for Sour Oil and Gas Fields

As oil and gas production expands into sour environments high in hydrogen sulfide, material reliability becomes critical. Learn how proper material selection and adherence to NACE standards can keep your system running efficiently

Need more information, support, or quotation?

Give us a call at 1-800-1234567 or message us.