Design and Assembly

Save time with standard and configurable fluid system assemblies.

Take the Building and Testing of Fluid System Assemblies Off Your To-Do List

Short of manpower? Our Swagelok-trained technicians can fabricate your fluid system assemblies for you. You will receive a professionally designed, repeatable solution with testing, inspection, and packaging included—all backed by the Swagelok Limited Lifetime Warranty.

We call these assemblies Swagelok® Custom Solutions. Custom Solutions are:

- Small or large assemblies, from a few components to complete panels or enclosures

- Always built from high-quality Swagelok components, with optional features like wiring, automation, transmitters, and more

- Built to your specific parameters

- Engineered to meet your unique needs

.jpg)

Explore Our Design and Assembly Services

.jpg?height=2000&name=Photography-Grab%20Sampling-2%20(1).jpg)

Grab Sampling System

Whether you need a closed-loop sampling into pressure-rated sample cylinders or want to collect liquids and nonvolatile process fluid into glass laboratory bottles for analysis, we offer ideal sampling panel options that are safe, intuitive, easy to maintain, and can be ordered with a single-part number.

.jpg?width=2000&name=Photography-Gas%20Distribution%20Program-5%20(1).jpg)

Gas Distribution System

We design Swagelok® gas distribution systems based on best practices. Our modular panels feature minimal threaded connections to reduce potential leak points, and they are intuitively labeled to promote safety, simple use, and maintenance. All our gas distribution systems are backed by the Swagelok Limited Lifetime Warranty.

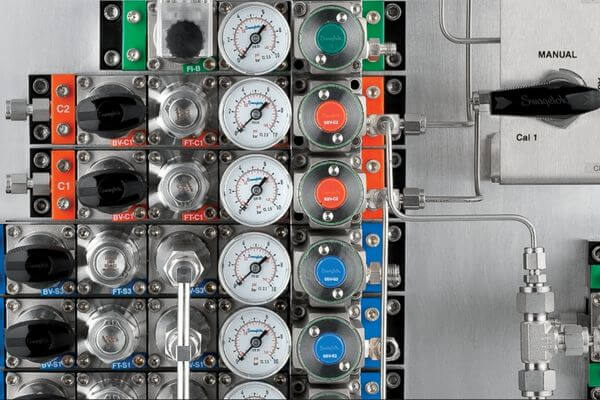

Swagelok® Analytical Subsystems(PrESS)

Swagelok pre-engineered subsystems (PrESS) for analytical applications are designed and assembled by fluid system specialists to be compact, accurate, and convenient to use.

Mechanical Seal Support

Our seal support systems are available in various American Petroleum Institute (API) plan configurations to suit your needs. They are assembled according to industry best practices as detailed in the fourth edition of the API Standard 682: Pumps—Shaft Sealing Systems for Centrifugal and Rotary Pumps.

Whether you have a preliminary drawing or just an idea, reach out for:

- CAD drawings

- Piping and instrumentation design (P&ID)

- Component selection and sourcing

- Bills of materials (BOM)

- Professional services, such as bending and welding

- Testing of system performance

- Professional packaging and delivery

Need more information, support, or quotation?

Give us a call at 603.8084.1818 or email us.

.jpg)