Chemicals

No matter what chemicals you are manufacturing, we offer the fluid system products and support you need to maximize the safety, efficiency, and reliability of your critical fluid systems.

Helping Chemical Companies Perform Under Pressure

The pressure to improve production performance is constant in the chemical and petroleum refining industry. Achieving peak output levels without reducing product quality means avoiding fluid system issues that lead to drops in efficiency, loss of primary containment, system downtime, or safety risks.

For process systems, the optimal pressure, temperature, and flow must be maintained. Analytical systems must also deliver timely and accurate results to ensure maximum profitability. Managing effectively can be a lot, especially across large operations featuring complex applications, but you don’t have to face these challenges alone. With process and analytical instrumentation from Swagelok®, you get the knowledge you need to drive solutions that optimize your process.

From maintaining accurate pressure, temperature, flow, and analytical measurements to improving the uptime of rotating equipment and emissions monitoring systems, the pressure to improve performance doesn’t stop. For that, you don’t need parts—you need partnerships. That’s what you get with Swagelok Malaysia.

.jpg)

When Safety and Flexibility are Paramount, CEPSA Chooses Swagelok

For CEPSA, a global energy company operating in the oil and chemical industries, safety and the availability of a range of reliable products is paramount. Learn how Swagelok fulfills those needs while also providing training and other support.

Our Services for the Chemicals Industry

System Evaluation and Troubleshooting

Our field engineers and technical advisors can assist with component selection and system design. After an evaluation of your current or proposed fluid processing and sampling systems, we will provide detailed recommendations on enhancements and installation best practices to improve overall reliability and efficiency.

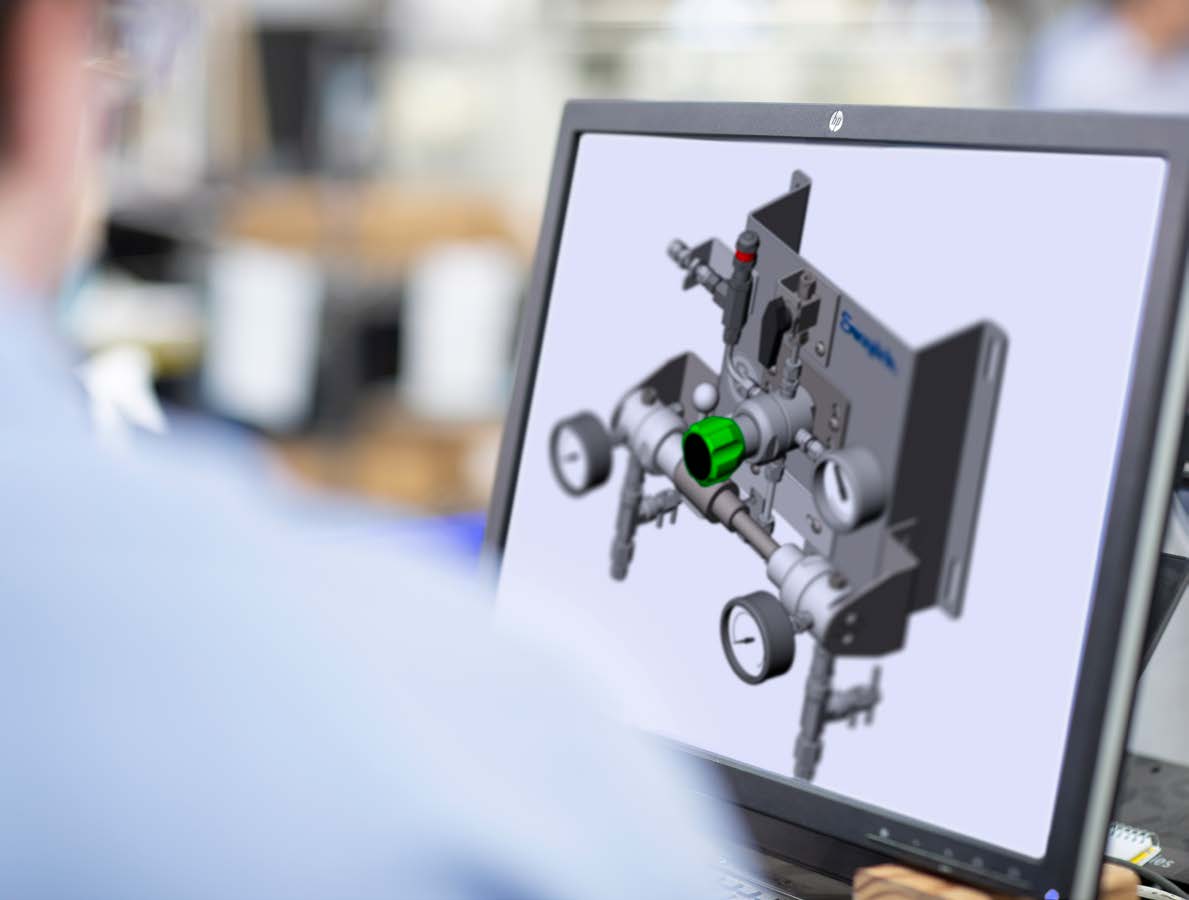

Design and Assembly Support

If you are experiencing issues with existing fluid systems or simply lack the resources to design and build complete, reliable systems, our specialists can help. Our team is trained and certified to build standard solutions for grab sample systems, mechanical seal support systems, gas distribution panels, and other instrumentation systems that handle liquids and gases.

Standardized, Practical Training

We can provide insights into what compatible materials choices, design considerations, and proven processes will help keep fluid systems operating effectively and sampling systems functioning reliably in harsh conditions. Our high-quality Swagelok® products for chemical processing and refining operations help you minimize downtime, maximize return on investment, and meet or exceed strict regulations and high standards.

.png?width=2000&name=Photography%20-%20Training%20and%20Education%20-%2027%20(LR).png)

Standardized, Practical Training

Our fluid and sampling system experts teach process and analytical engineers, technicians, and maintenance personnel to do their jobs safely and to recognize and solve persistent fluid or sampling system issues through in-depth, hands-on training programs. Swagelok training courses provide valuable and practical tools for meeting day-to-day challenges, helping new team members and industry veterans alike improve their fluid system design, operation, and maintenance capabilities.

Our Products for the Chemicals Industry

Fittings

Whether you need fittings for corrosive environments, extreme temperatures, or high pressure, we have a wide variety of reliable, leak-tight fitting products for use in chemical processing

Valves

Our durable, dependable valves perform reliably even after years of use in demanding applications. Find the ball valves, check, valves, needle valves, relief valves, manifolds, and more needed to appropriately control flow in your small-bore fluid systems.

Regulators

Maintain precise pressure control throughout your fluid systems and throughout your facilities with pressure-reducing (spring-loaded or dome-loaded), back-pressure (spring-loaded and dome-loaded), and specialty regulators capable of handling a wide range of range of pressure and flows.

Hoses & Flexible Tubing

Choose from millions of variations of metal core, PTFE/PFA core, rubber core, and thermoplastic core hose and flexible tubing options to find products that meet the performance criteria of your chemical processing applications.

Filters

Avoid particulate contaminants leading to off-spec products, inaccurate analyzer readings, or other problems downstream with particulate filters and coalescing filters designed to preserve the integrity of your processes.

Measurement Devices

Maintain optimal fluid conditions throughout your plants with measurement devices such as pressure gauges, pressure transducers, flow sensors, flowmeters, thermometers, and additional measurement devices that are easy to use and read.

Tubing and Tube Accessories

Find metal tubing with the material composition and performance characteristics needed for your chemical processing, as well as accessories used to cut and deburr, bend, swage, and support tubing.

.jpeg)

Welding Systems

Weld consistently and efficiently with the Swagelok orbital welding system, which provides cost-effective, reliable orbital gas tungsten arc welds (GTAW) for both tubing and pipe.

Swagelok® Analytical Subsystems (PrESS)

Swagelok pre-engineered subsystems (PrESS) for analytical applications are designed and assembled by fluid system specialists to be compact, accurate, and convenient to use.

.jpg)

Grab Sampling System

Customizing Swagelok® grab sampling systems allows for safe, efficient sample capture while meeting your specific plant application needs. The panels are available in a variety of configurations and advanced features.

.jpg)

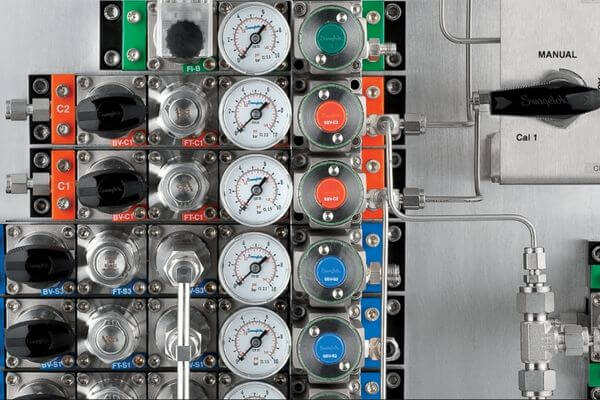

Gas Distribution System

Swagelok engineers build standardized, configurable gas delivery systems to help protect system operators, increase process uptime, and improve process accuracy and repeatability.

How We Can Help the Chemicals Industry

Increasing Safety

We understand that safety is our customers' top priority, especially in environments where highly volatile, caustic, or otherwise-hazardous fluids are transported throughout plants. That is why we provide leak-tight components with the necessary performance characteristics to prevent fluid from escaping your systems, assemblies designed for minimal connection points, and supporting services based on decades of experience serving Malaysia's chemical & refining industries.

Maintaining Uptime and Reliability

We understand that safety is our customers' top priority, especially in environments where highly volatile, caustic, or otherwise-hazardous fluids are transported throughout plants. That is why we provide leak-tight components with the necessary performance characteristics to prevent fluid from escaping your systems, assemblies designed for minimal connection points, and supporting services based on decades of experience serving Malaysia's chemical & refining industries.

Increasing Safety

We understand that safety is our customers' top priority, especially in environments where highly volatile, caustic, or otherwise-hazardous fluids are transported throughout plants. That is why we provide leak-tight components with the necessary performance characteristics to prevent fluid from escaping your systems, assemblies designed for minimal connection points, and supporting services based on decades of experience serving Malaysia's chemical & refining industries.

Resources

Improve Gas Distribution Safety and Efficiency

Gas distribution systems are crucial for helping labs, test centers, and industrial facilities operate at peak efficiency. Learn more about optimizing gas delivery system health and safety, reducing costs, and equipping your team for success. Read More.

Seven Tips for Effective Plant Turnarounds

A plant turnaround can be a big headache for a chemical plant or refinery—but it doesn’t have to be. Learn seven strategies for more effective turnaround management. Read More.

INEOS Petrochemical Safety Case Study

Swagelok’s contribution to the safe operation of INEOS’s petrochemical facility in Cologne, Germany, maps back to the close collaboration between the two companies. Learn how Swagelok’s trusted reliability helps INEOS ensure petrochemical safety. Read More.

Need more information, support, or quotation?

Give us a call at 603.8084.1818 or email us.