Semiconductor

Whether you work for a tool OEM, a chip fabricator, or another company supporting the semiconductor industry, we here to help you maximize profitability and compete effectively in a swiftly changing marketplace with our fluid system products, technical expertise and service capabilities.

Productivity for Today. Innovation for Tomorrow.

We understand that innovation is the foundation of the semiconductor industry success. Relentless advancement in electronic technology demands more complex, more compact microchips, and competition is fierce.

For over five decades, Swagelok® has provided high-quality fluid system components and support to semiconductor tool manufacturers and chip fabricators to help them evolve production processes and equipment while maintaining the precision and cleanliness needed to sustain profitability. As a result, we have the privilege of working with leading semiconductor companies in Malaysia who trust us to help them increase chip yield and quality, reduce lifecycle costs, and maintain safe fluid system operations.

We provide support to the local semiconductor industry, helping them access the fluid system products they need in a timely manner and troubleshoot problems as they arise to minimize uptime and maximize profitability. Whatever fluid system challenges you face, work with the company trusted for decades to help the semiconductor industry evolve—Swagelok Malaysia.

How to Use ALD Valves in Ultrahigh-Purity Production

See how Swagelok facilities are designed to produce ultrahigh-purity fluid system products for the semiconductor industry in this virtual tour. Our facilities adhere to the strictest quality and cleanliness standards to ensure our products meet your needs.

Our Services for the Semiconductor Industry

Field Engineering

Our field engineering team can help analyze your fluid systems for problems and recommend solutions to help you improve process reliability, find opportunities for efficiency, and improve operational safety.

Onsite Services

Whether your processes are designed for ALD film deposition, etch, or photolithography, our specialists can conduct fluid system site surveys, hose advisors' evaluations, or leak detection audits to make your facility safer and more efficient.

Design and Assembly Services

Receive design consultation and professional assembly of high-quality standard and configurable fluid subsystems constructed and tested according to best practices.

.png?width=2000&name=Photography%20-%20Training%20and%20Education%20-%2027%20(LR).png)

Fluid System Training

Discover a variety of training courses designed to enhance your skills for developing, building, and maintaining fluid systems, including orbital welding, materials science, high-purity fittings essentials, and more.

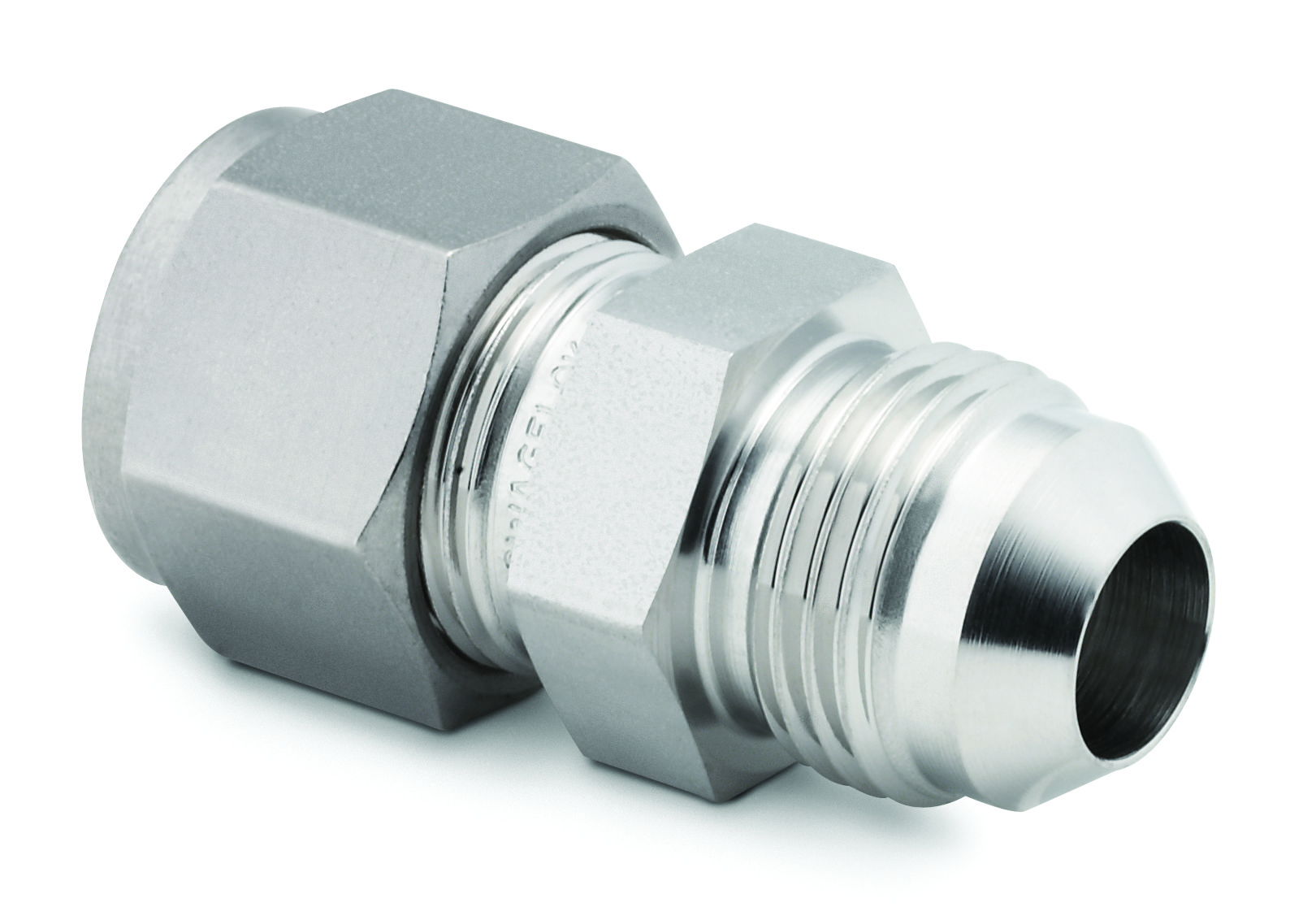

Our Products for the Semiconductor Industry

Valves

View options including high-performance UHP ALD valves for semiconductor atomic layer deposition production and additional diaphragm valves, bellows valves, check valves, and specially configured valves and accessories.

Hoses and Flexible Tubing

Find the right hoses for your semiconductor production environment, from insulated hoses for chiller applications to other PTFE hose, metal hose, hybrid hose, and rubber hoseoptions. You can also choose from convoluted metal tubing or PFA flexible tubing products designed for semiconductor production.

Regulators

Control pressure effectively throughout your fluid systems with options that include spring-loaded and dome-loaded pressure-reducing regulators and compact high-purity, high-flow gas regulators.

Filters

Remove particulate contaminants with Swagelok UHP inline gas filters in demanding applications where purity is a requirement and space is limited.

.jpeg)

Welding System

Weld consistently and efficiently with the Swagelok orbital welding system, which provides cost-effective, reliable orbital gas tungsten arc welds (GTAW) for both tubing and pipe.

Tube Benders

Swagelok’s easy-to-use hand tube benders, bench top tube benders, and electric tube benders provide high-quality bends on fractional and metric tubing, reducing installation time and effort.

.jpg)

Gas Distribution Systems

We design Swagelok® gas distribution systems based on best practices. Our modular panels feature minimal threaded connections to reduce potential leak points, and they are intuitively labeled to promote safety, simple use, and maintenance. All our gas distribution systems are backed by the Swagelok Limited Lifetime Warranty.

How We Can Help the Semiconductor Industry

.png?width=628&height=628&name=Growth_OutlineCircle_80Gray%20(1).png)

Higher Speed, Yield, and Profitability

As the miniaturization of process nodes continues, Swagelok components and solutions give our customers access to the UHP cleanliness levels and extreme dosing precision needed to maintain high yields.

We also give them the ability to experiment with chemistries and processes that require performance at higher temperatures or flow rates. For applications beyond chip-manufacturing tools, we provide reliable fluid system components designed to perform well throughout a variety of industrial facility applications, helping fabricators avoid downtime. As processes evolve, our team can help you design solutions to production challenges so that you can maximize your throughput of high-quality products and your ability to innovate.

Reduced Total Lifecycle Costs

Given the cost of semiconductor production and the value of the outputs, downtime must be avoided to maintain profitability. To minimize total cost of ownership, Swagelok components are engineered to deliver consistent performance over millions of cycles in challenging process environments. We know that the exploration of new precursor gas options for deposition requires fluid system components to withstand hotter production processes and more corrosive media, and we have designed our products to last in challenging conditions so that you can replace components less frequently, minimizing process downtime and maximizing throughput.

Consistent Performance, Consistent Experience

We have the people, processes, and technology to give you confidence that you will receive the consistency you need from product to product across your international operations. That consistency starts with Swagelok’s strict manufacturing process controls and is supported by associates who help you maintain reliable performance throughout the full lifecycle of your fluid systems. Our fluid system specialists provide technical support, training, evaluation and advisory services, design and assembly support, and other insights from hundreds of locations across the globe. Find the support and reliable components you need to deliver the quality and consistency your customers expect when you work with Swagelok Malaysia.

Safe Fluid System Operation

Given the nature of the chemicals used in semiconductor facilities, safety precautions are paramount. Fluid leaks must be taken seriously, and avoiding them requires choosing every system component carefully. Safe component selection matters far beyond semiconductor manufacturing tools. Something as simple as condensation on the outside of a chiller hose that is not properly insulated could result in slip hazards or downtime until a puddle can be identified. We provide a comprehensive portfolio of leak-tight, corrosion-resistant fluid system components, and assemblies that are properly constructed to promote safe conditions in your facilities.

Resources

Building a More Profitable Semiconductor Fab

Learn why choosing high-quality fluid system parts and assemblies can contribute to faster semiconductor fabrication facility construction, and lower total cost of ownership over the facility’s lifetime. Read More.

Why Fast Support Matters for Semiconductor Fabs

Reducing total cost of ownership for semiconductor fabs is possible by working with suppliers that can provide fast, local support for critical challenges. Find out how Swagelok can help. Read More.

Solving Semiconductor Fabrication Challenges with Insulated Hoses

The right insulated hose solution can help solve some common challenges associated with the highly precise semiconductor fabrication process. Read More.

Need more information, support, or quotation?

Give us a call at 603.8084.1818 or email us.