Advancing Your Hydrogen Projects: Ensuring Reliability Beyond Traditional Oil and Gas Systems

Azwan Shuaib, Proposal Engineer, Swagelok Malaysia

The global shift toward clean energy demands a fundamental change in how fluid systems are engineered. For companies transitioning from traditional oil and gas (O&G) operations, it’s critical to understand that standard oil and gas components and design principles are inadequate for hydrogen applications.

Designing safe, efficient, and reliable systems for hydrogen production, transport, and dispensing requires a specialized approach.

This ensures system integrity, operational efficiency, and maximum safety—factors essential for your project’s success and optimizing the Levelized Cost of Hydrogen (LCOH).

The Hydrogen Integrity Challenge: Why Standard Components Fail

The core challenge in hydrogen system design is the nature of the molecule itself.

As one of the smallest molecules, hydrogen is notoriously difficult to contain, requiring a level of leak-tightness far beyond oil and gas standards.

Challenge |

Impact on Your Operation |

Our Solution |

|

Micro-leak Paths |

Hydrogen easily escapes through microscopic imperfections (continuous pore structures) in traditional fittings, leading to costly gas loss and safety hazards. |

Next-Generation Fittings engineered for secure, repeatable, and ultra-leak-tight sealing under high pressure and thermal cycling.

|

|

Hydrogen Embrittlement |

Hydrogen diffuses into certain metal microstructures, reducing the material's ductility and resistance to fracture, and poses a severe long-term safety and asset integrity risk.

|

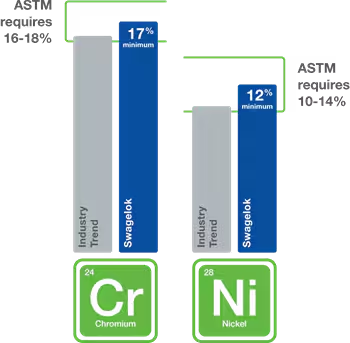

Enhanced Material Selection with specifications such as high-quality 316 stainless steel (minimum 12% nickel) helps stabilize the microstructure and reduce the risk of embrittlement. Swagelok® 316 stainless steel is engineered with a specialized formulation that delivers improved strength and corrosion resistance, offering superior performance in hydrogen environments.

|

Design Imperatives: Secure Your Hydrogen Investment

Our expertise ensures your system is designed from the ground up to overcome these challenges, delivering a reliable, long-lasting asset.

- Optimal System Layout: Minimize Risk and Cost

- Tubing over Piping

We prioritize small-bore tubing systems and precision tube-bending techniques. This approach strategically replaces high-risk fittings with reliable tubing runs, drastically reducing potential leak points and enhancing overall system integrity. - Optimized Line Sizing

Line sizing is a direct factor in your Levelized Cost of Hydrogen (LCOH). We balance flow rate requirements with material costs and pressure drop to avoid the unnecessary capital expenditure associated with oversized lines and larger, more expensive components (compressors, valves).

- Tubing over Piping

- Safety Engineered in Compliance and Assurance

- Containment Integrity

Using components certified and proven to be leak-tight against small-molecule hydrogen at extreme pressures (up to 1050 bar and beyond). - Standards Adherence

Ensuring all designs and component selections meet stringent international codes and standards, including NFPA 2, and ISO/ TS 19880.

- Containment Integrity

Specialized Expertise for Project Acceleration

By partnering with Swagelok Malaysia, you gain access to the specialized knowledge and proven components needed to accelerate your project timeline while guaranteeing maximum safety and long-term asset integrity.

1) Hydrogen-specific Expertise

Our team helps you mitigate risks such as embrittlement and leakage through deep knowledge of materials science and fluid dynamics, preventing costly failures before they occur. This expertise delivers measurable value—our ultrasonic leak detection service helped one customer identify and repair system leaks, resulting in $6,078 in annual gas savings, effectively paying for the service entirely.

2) Component Reliability Assurance

We reduce downtime and maintenance by providing fittings and valves engineered for superior leak-tightness and long-term durability. This reliability is demonstrated by a leading Green Hydrogen OEM, whose team successfully remade our fittings more than 20 times without a single leak in high-pressure testing conditions, significantly cutting production costs and eliminating the likelihood of future onsite maintenance.

3) Regulatory Compliance Support

We help you accelerate certification timelines and meet rigorous industry standards critical for large-scale energy initiatives. Our collaboration with Luxfer Gas Cylinders is one example: we developed and supplied certified fittings and valves within a demanding 14-month timeframe, enabling them to achieve required certification for hydrogen fuel-cell vehicles on schedule.

Why Partner with Us for Your Hydrogen Projects?

We provide the assurance and technical depth you need to confidently navigate the complexities of the new hydrogen energy landscape. Together, we can turn these challenges into efficient, safe, and reliable outcomes for your projects.

Reach out to us at malaysiaenquiry@swagelok.com to discover how we can help your hydrogen project achieve maximum safety, reliability, and efficiency.

Related Articles

.jpg)

Hydrogen: A Truly Sustainable Alternative Fuel

Have questions about the sustainability profile of hydrogen fuel? We have answers—learn more about hydrogen production and the fuel’s potential as a viable, sustainable power source.

.jpg)

Why Hydrogen Is a Cost-Effective Fuel

Is hydrogen too expensive for mass adoption as an alternative fuel? The answer is simple: No. Learn why hydrogen fuel prices continue to fall, making it a viable alternative to fossil fuels.

%20(1).jpg)

Have Hydrogen Vehicle Range Anxiety? Here’s Why You Shouldn’t

Do hydrogen fuel cell vehicles have what it takes to travel comparable ranges to gasoline or diesel vehicles? We have the facts. Learn why hydrogen is a viable fuel for longer-range travel.

Need more information, support, or quotation?

Give us a call at 603.8084.1818 or email us.